Basic blender went bad (motor ran but spindle wasn’t rotating). I wanted to disassemble to see if it could be repaired. Three of the four screws were Phillips head. I had to cut the casing open in order to discover why I couldn’t unscrew the fourth. It was a slotted spanner.

Buy a security bitset! It is surprisingly handly to have around. Sometimes, I’ve needed a certain screw size that they don’t have in imperial, but they do have in metric at the hardware store. But it’s a security bit only.

They also work on regular, non security bits in a pinch.

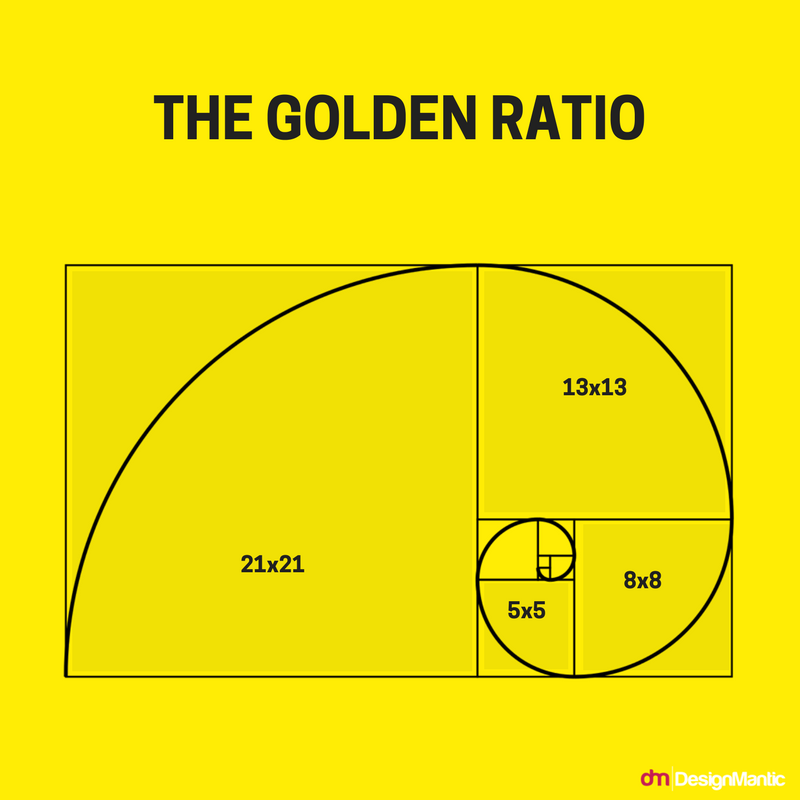

Comon, do some reading:

I had to cut the casing open in order to discover why I couldn’t unscrew the fourth.

Phone camera; $30 digital microscope; $30 Endoscope. There are just so many better ways available to look down a hole to see what’s at the bottom than to tear apart the space around it.

Spanner bits are available in sets starting as little as $7. They are anything but “non-standard”.

The bit set and tool set from IFixIt has those. I’m not sponsored by them in any way, but I will shamelessly recommend their tools when I can because they’re objectively good for this kind of stuff.

Looks like a job for a regular flathead and a grinding wheel.

Honestly, if you don’t have a set of security bits I would be concerned about you opening up a blender.

honestly i’d be concerned about somebody without tools opening a blender. Why are they in there? How did they get in it? And what did the blender do to them?

I mean a blender isn’t exactly the worst things to have security bits on.

Really? It seems to me that if you believe blenders should be tamper-proof, you must believe that all appliances should be.

A single tamper proof screw that all that’s required to remove is knowledge… Yes. Unfortunately stupid people try to do things they shouldn’t and that single screw removes an idiots ability to sue after they screw with things they know not.

Or they could just not be able to sue a company for being an idiot 🤷♂️

There’s the way the world works and the way the world aught to work according to xyz.

One is reality the other isn’t. Realistically if you don’t expect a security screw when taking apart dangerous electronics you probably shouldn’t be working on them.

Personally to me I think we need to stop idiot proofing everything.

I’m not saying remove all safety standards or warnings but we’ve gone too fuckin far to the point a complete moron has to be protected and treated like a child which just holds the rest of us back.

I’m all for having less idiots but reality differs.

The tamper proof screw is NOT there to protect you, It’s there to discourage repairs plain and simple. A warning label is more than adequate on other blenders, why not this one? In fact, there are plenty of dangerous devices I can think of that don’t need to be locked down to prevent lawsuits. A lawsuit would require negligence on the part of the manufacture and while you’re trying to say by not locking it down it could be considered negligence you’d be wrong. Otherwise I could quit my job and just file lawsuits all day. Let’s not try to defend these companies that engineer planned obsolescence into their products. All they want is to be the sole repair option (big profit margins) or have you buy a new over priced high markup item. Nevermind the waste generated by hrowing away perfectly good products that a simple easy repair would fix.

The tamper proof screw is NOT there to protect you, It’s there to discourage repairs plain and simple.

Point to where I said it was there to protect you. It’s quite literally to avoid lawsuits putting the screw there implies it’s meant to be taken apart by a professional, not Ted down the street who stopped school in third grade.

All they have to do is point to that screw and the lawsuit dies then and there no further action.

It’s also not planned obsolescence in this case, it’s a barrier to repair. Literally a hoop too small to jump through that catches the dumbest of the well meaning. It would be planned obsolescence (arguably) if it prevented repair, it doesn’t it simply complicates it. It’s the same reason your seatbelt part ≈00 is held down by a large torx t50-60 and no longer a 15mm bolt.

You lost me on the seatbelt thing. What’s going on there?

It’s quite literally to avoid lawsuits putting the screw there implies it’s meant to be taken apart by a professional, not Ted down the street who stopped school in third grade.

You got it so backwards…

Madison, I’m not really sure what you’re argument is here. Let’s look at your seat belt argument. Torx (or star bits as they’re now called since Torx is a brand name) has become a ubiquitous standard in the automotive world and absolutely irrelevant to the poor point you’re trying to make. Auto makers use star bits because they enable a rounded dome shape that is smaller and requires no space around the bolt head to accommodate a thick socket. You may have assumed it was to prevent removal but no auto maker has ever declared that as a reason. Considering that even basic starter tool kits come with star bits these days I’d say that makes them a poor choice as a lawsuit prevention method. There are too many other “dangerous products” out there that don’t have silly screws and yet somehow are able to avoid frivolous lawsuits. I’m not sure why defending this practice is the hill your want to die on but making repairs difficult to avoid a lawsuit is something only a sucker would believe.

and that single screw removes an idiots ability to sue after they screw with things they know not.

It’s not how it works…

That’s exactly how it works and honestly this photo series is a pretty good illustration of why it works.

Grind a flat

I didn’t even know that that screw type had its own name until I saw it in another comment, but the first thing I thought was to just do what you said.

How are you supposed to grind a flat on a screw recessed 2" in a hole?

Take a flat screwdriver and moubt it on a vice. Take your angle grinder, mount a disk for metal grinding. Grind away the middle of the flat screwdriver head. Done it before for the exact same purpose.

I had drill bits for such screws for decades, never had the reason to use them though. It’s nice to see that there’s a use for them after all!

Well, the drill bit wont fit if the hole is too long and thin, so its not always quite that easy.

If you have a Dremel, I bet you could take out the center bit and use a regular slotted screwdriver.

$10 says it was recessed before op cut the base off, making it impossible without damage to slot the screw with a Dremel.

So you use the dremel to cut a groove into your screwdriver instead.

At that point, just buy the correct bit for the job.

Damn, I didn’t even think of that. It would be ruining a good screwdriver, but you could just use an old worn flat-head drill bit.

Good call, either way.

👆

Where’d you get such a big brain

Edit - ah, since you can’t see the screw until you cut away at the product, the company is still going to frustrate even the crafty DIYers

make a print with a bit of putty on a stick ?

Great idea! Much more reasonable than trying to get a fiberoptic kind of camera down there.

$30 bucks. An endoscope is $30 bucks, and well worth it.

ah yes a classic we call this a flathead, but without the part of the flathead that makes it good at not being a shit screw, but also it’s located now so the driver doesn’t slip out of the screw, so it’s actually kinda better than just a flathead screw, but it probably strips a lot easier than a flathead, since there’s a lot less surface area on it. Screw.

edit: there’s a lot of people coping on this thread for some reason, bro it’s a blender, who cares, it’s like 20 dollars, 99% of the population is buying a new one anyway.

yeah, they’re missing the fact it was posted in right to repair maybe.

idk how anybody would be missing that. I think people are just being their usual selves.

1% is buying a new one anyway, 49% repairs blender, 25% dreams of blender and 25% never

installedheard of blender.i didn’t know there was a repair market for the free open source application of blender, that’s cool

A complete set of security screw bits is ~20 bucks and they’re far more useful than I realized until I acquired them.

Comon, do some reading:

I had to cut the casing open in order to discover why I couldn’t unscrew the fourth.

Do some comprehending. Yes he had to do that. But it was because he was using the wrong bit.

Phone camera; $30 digital microscope; $30 Endoscope. There are just so many better ways available to look down a hole to see what’s at the bottom than to tear apart the space around it.

OP didn’t have to handle it how they did, at all.

He had to see which bit to use

Phone camera; $30 digital microscope; $30 Endoscope. There are just so many better ways available to look down a hole to see what’s at the bottom than to tear apart the space around it.

That can be accomplished non-destructively.

Oh, I have that bit. Its not even the weirdest

hahahahahaha, about three years ago now, I bought a hunting knife from Amazon that came with a sheath which had a belt clip that was held on by one of these fucking screws.

at the time, i couldn’t figure for the life of me what it was or if there was a tool for this so I went to Home Depot, bought a .99 cent flathead our of their bargain tubs, took it to their tool rental department where they also will cut metal for you if you ask nicely. had them make a notch in the top of the flathead, brought it home and after some filing got it to get in there and loosen up this devil screw top.

now i know it’s called a U or H type screwdriver. my way was cheaper, but nice to know the real solution now.

It’s called an “H-type” head. I found some tools for that on eBay but was reluctant to spend any money on something I’d probably never need again, ever. But this video shows a hack using scissors.

https://www.youtube.com/watch?v=GA6_S9YkZEc

I didn’t have a pair laying around that worked but the video inspired me to MacGyver my way to remove that aberration against all that’s good in humanity.

The security bit is doing it’s job. If this is a barrier for someone, then they aren’t the kind of person who should be playing with the internals of a dangerous electronic device.

a dangerous electronic device.

i feel like if someone has the capability of bitching about a security screw on the internet, they probably have the intelligence to unplug a blender from the wall.

If this is the standard for security screws, hex/torx will almost certainly do it’s job, but significantly better.

This is the same person that had to smash open the device like a caveman banging rocks together. Posting a rant online instead of just buying a security bit isn’t a good second step either. OP may certainly be the exact type of person to keep out: bold enough to try to break open electronics, but stopped by a fairly standard security bit.

but stopped by a fairly standard security bit.

Did you read post. Before writing was best time, but second best is now.

Here’s quote if you have eyesight like mine:

I had to cut the casing open in order to discover why I couldn’t unscrew the fourth.

The screw head was at tho bottom of a 2 inch shaft.

They didn’t have to cut shit.

Which was discovered AS RESULT of cutting open.

You are quite spammy, aren’t you?

No, the shaft was not uncovered as a result of cutting the thing open. They were able to reach the screw-head with a regular screw-driver, just not turn it. Says right there in the post.

Learn to read, stop spamming people with your shit takes, and sure, let’s pretend replying to your copy-pasted bullshit with more copy-pasted bullshit is somehow worse. Anything to feed trolls like you.

maybe caveman want motor out of blender, and screw is hinderance to motor collection. Don’t judge a mans cave by the lack of blenders. Judge it by the principles held within!

Regardless, security bits are a skill issue, and i will not stand for them. They make cars with traditional bolts and nuts, those are perfectly accessible to the average person, yet people killing themselves with their bad car repairs, is disconcertingly low. They’re bad for repairability, they’re bad for the environment, and most importantly, they waste time and money for no fucking reason.

Seatbelts tend to be held in with Torx-head bolts. Right bicycle pedals have left-hand-threaded studs. Spanner-screws are a standard you’ll find drivers for in any good security or electronics/small-appliance repair set.

Odds aren’t that far off that this screw was chosen for their blenders decades ago when this screw-driver was more common, and this one part was never updated as the design … “evolved”.

i’ve got no problems with torx (it’s one of the best driver designs) and nothing wrong with left hand thread, as you said, it’s needed for bicycles, but using proprietary “security” bits is just, less than acceptable in the modern day and age.

Though i am inclined to agree with you on the design theory, it’s more than likely they have billions of those little proprietary things kicking around in a warehouse, and there’s just no reason for them to get rid of them.

Shit take.

My library has a lendable “Ultimate Screwdriver Kit” that has every bit size and type I’ve ever heard of, security Torx, pentalobe, oval, gamebit, spanner, etc etc. Also a bunch of different styles of bit holder, and a bunch of attachments like angle adapters, depth setters, torque limiters, etc. Only tangentially relevant I guess… but if you run into a problem like this again, check your local library to potentially avoid having to buy obscure bits online!