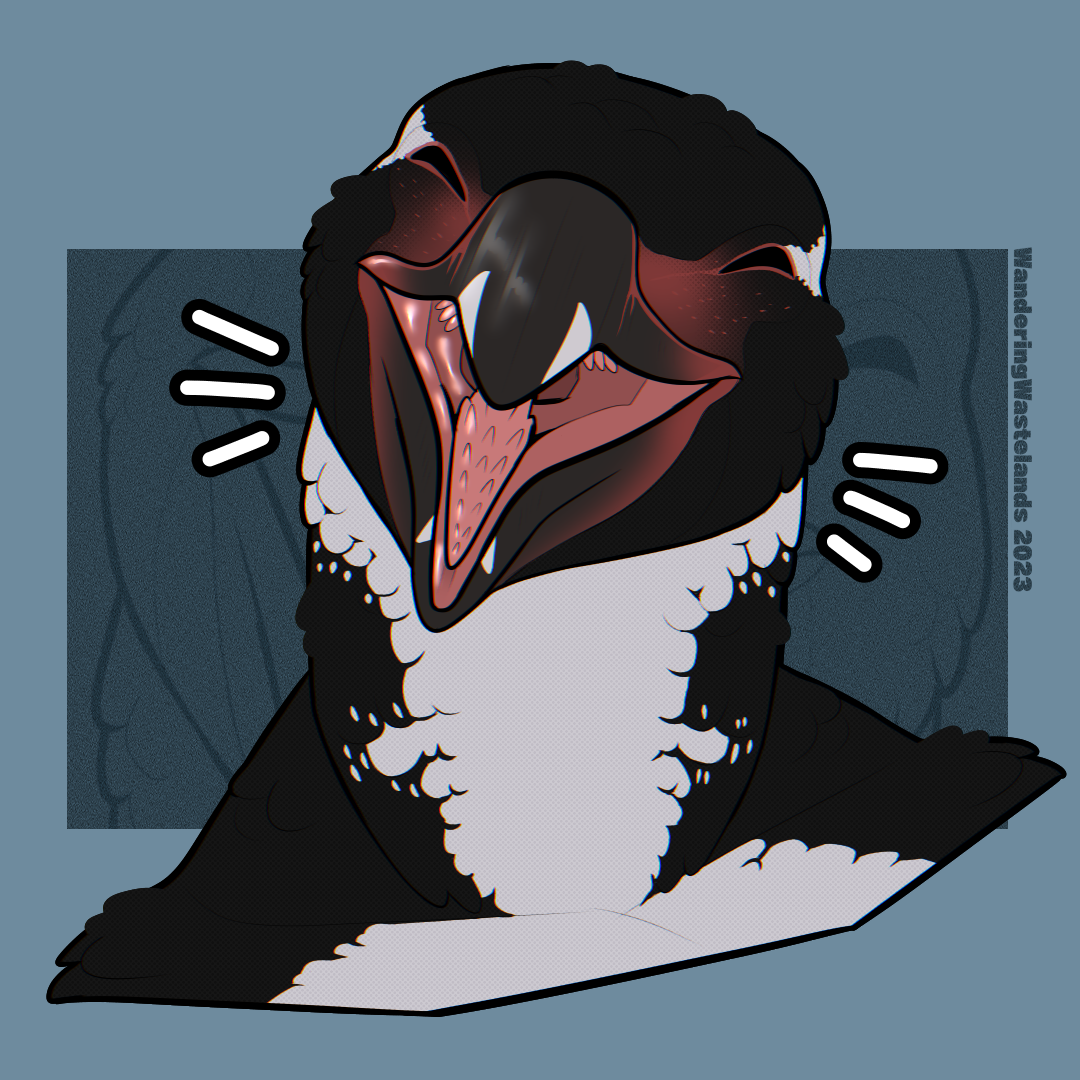

I have always wanted to try printing larger, using a bigger nozzle - just got around to swapping to a .6mm in my MK3S+. Printed a gift for a childhood friend. 300% size. Took just under 10 hrs. With the slicer settings on .4mm it was over 17hrs.

When it works, it’s pretty great. I’ve got a weird overextrusion issue to fix on my MK3S+ with the 0.6 nozzle, but the prints themselves are tougher and faster.

Did you play around with different filament settings or presets? Most importantly extrusion multiplier?

Measuring the filament might be a good idea too, maybe slight differences are becoming visual with a bigger nozzle

How did that print so well without any supports?

That is a very good question. There aren’t any insane overhangs, just a few tricky spots. I had print he same thing smaller, so I knew it would be okay. I think the file actually mentioned in the notes that you COULD print it without support.

I was shocked too at first, but then i realized the same thing, i don’t see anything problematic, what a great model